2024. 6. 18. 17:35ㆍIGBT 조립 장비

IGBT 조립 공정도 및 IGBT 실장 장비에 대한 내용 입니다.

PDF file

pin 번호가 있어 자료 Open을 위하여 info@namaSMT.com or T 02. 3141 2111 문의 하여 주시기 바랍니다.

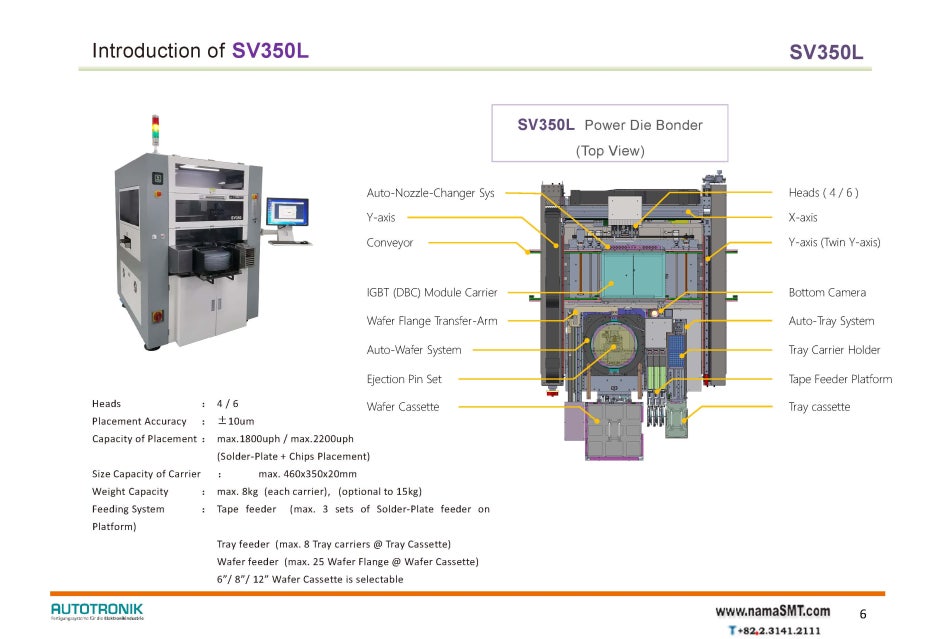

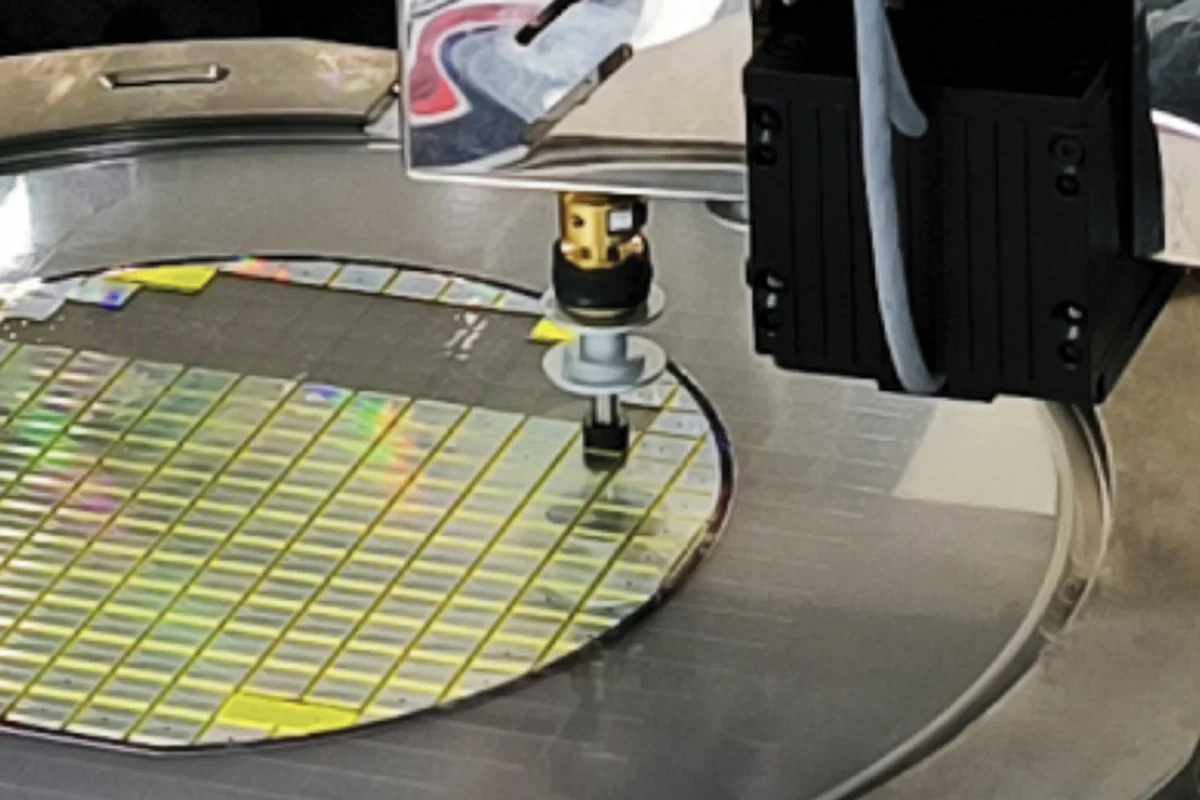

The latest IGBT Power Diebonder of AUTOTRONIK is introduced in the following sheets. Its advantages are these multiple types and specifications of materials are compatible with one high-precision mounting equipment at the same time.

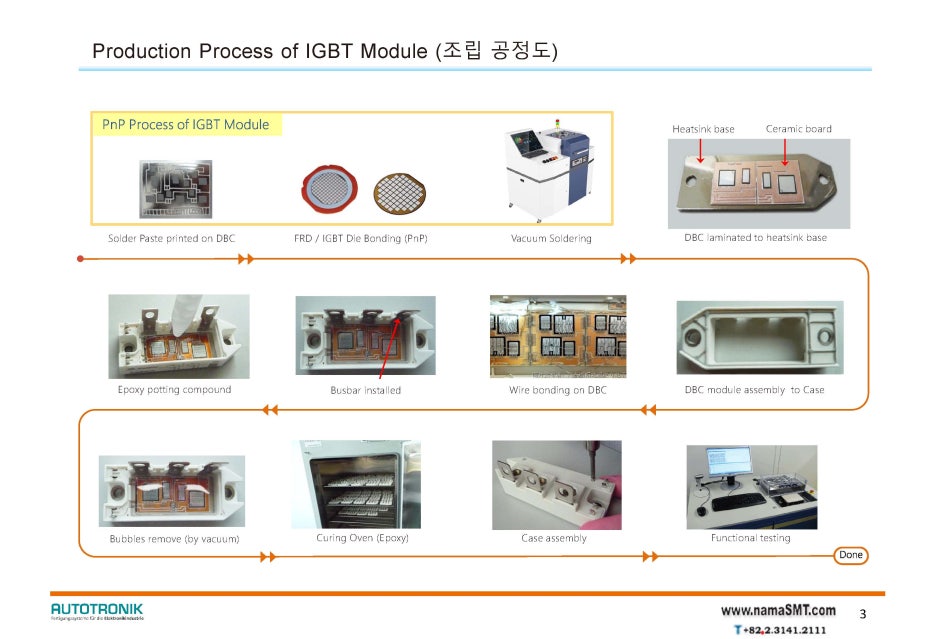

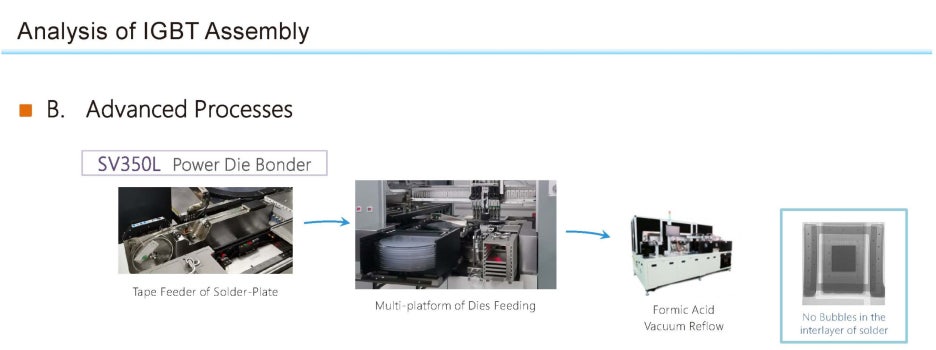

Analysis of IGBT Assembly

Process Flow

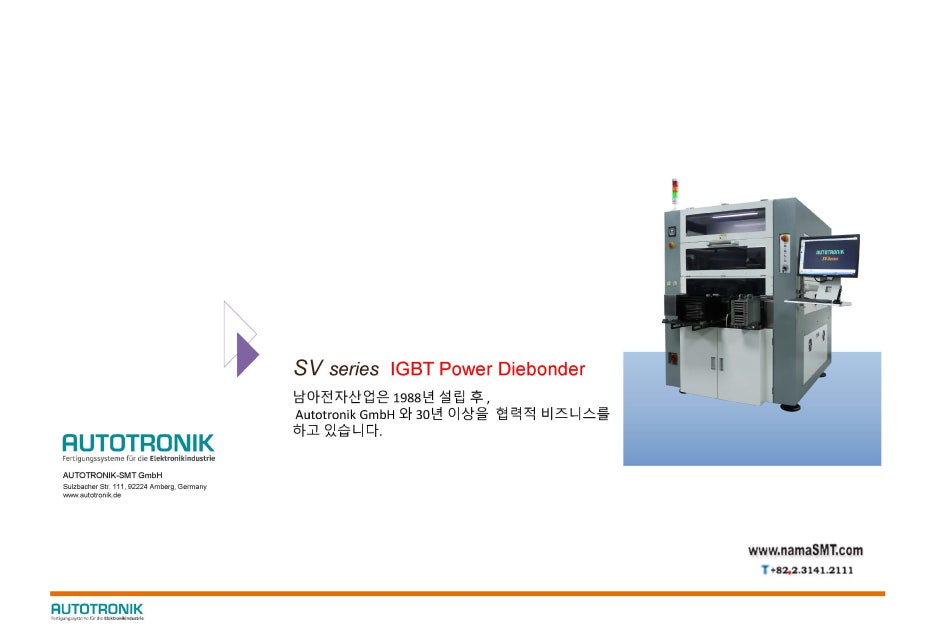

DBC boards carrier loading to SV350L à Solder-plate placing à Chips/Dies placing (Tape/ Wafer/ Tray feeder) à Soldering (Formic Acid Vacuum Reflow)

Advantage

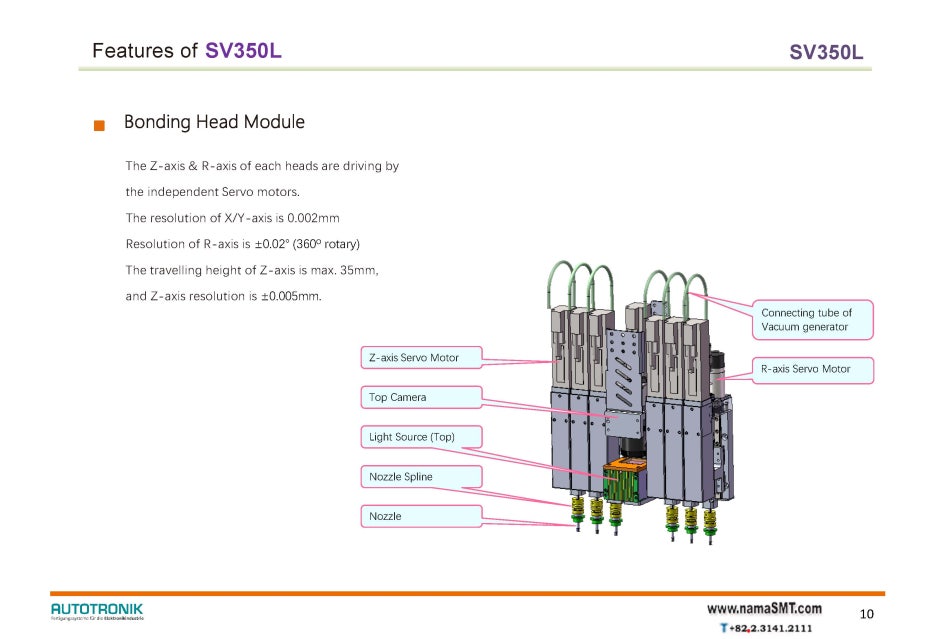

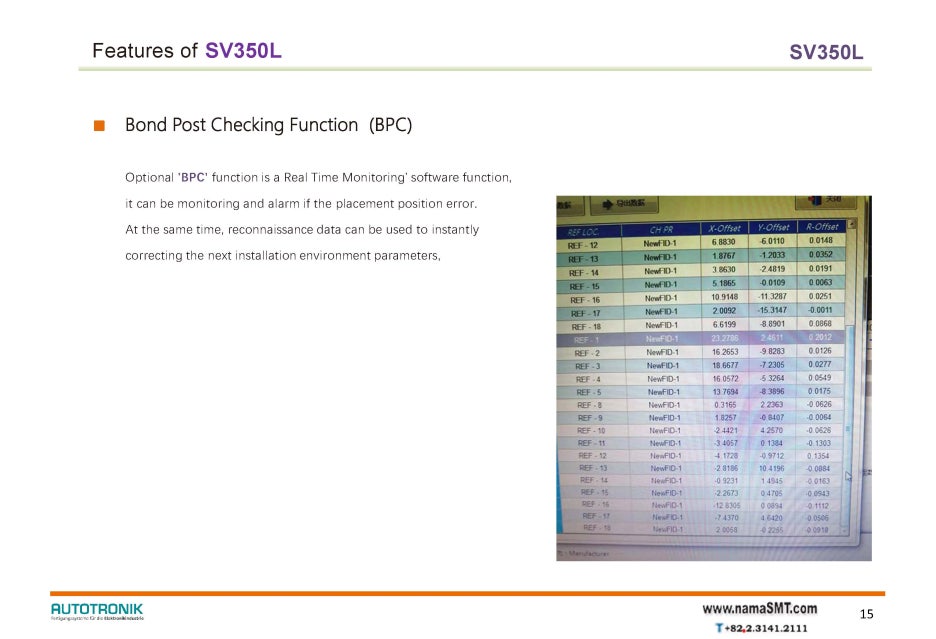

Use the SV350L equipment specially designed for IGBT power module chips mounting, to complete the entire the chips assembly of DBC module :

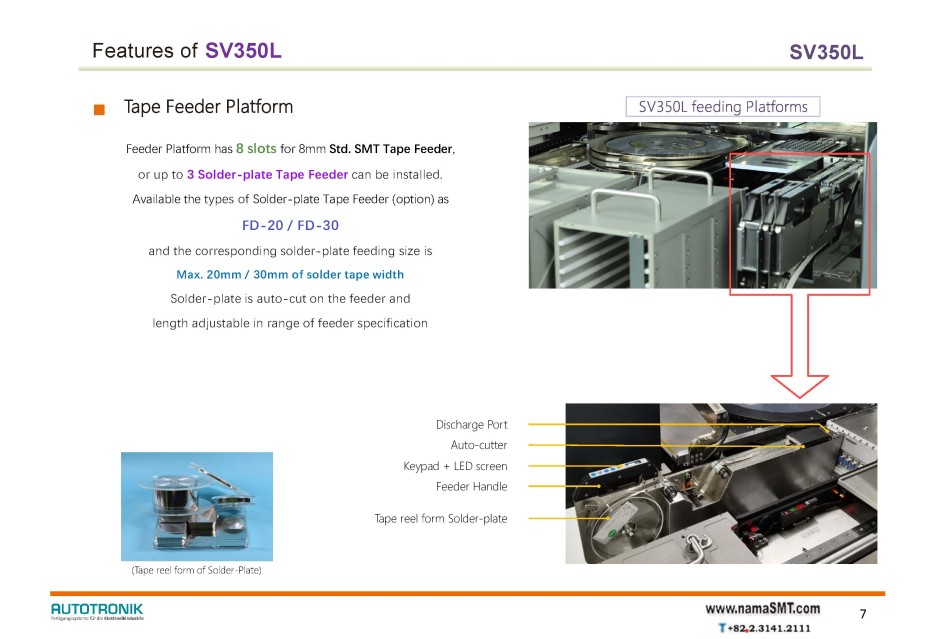

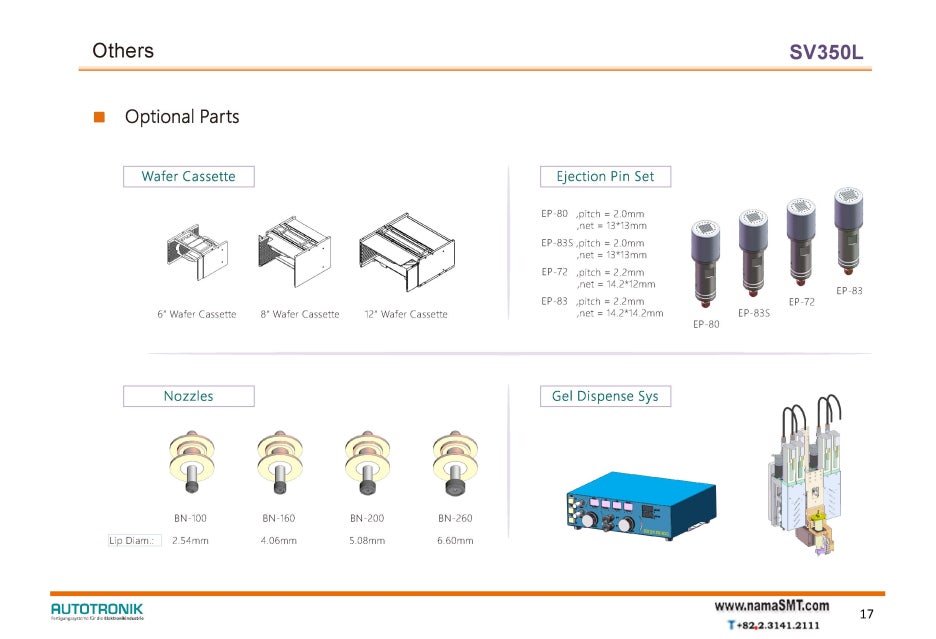

1. SV350L is compatible with SMT tape feeder, Tray feeder, and Wafer flange feeder to loading and unloading;

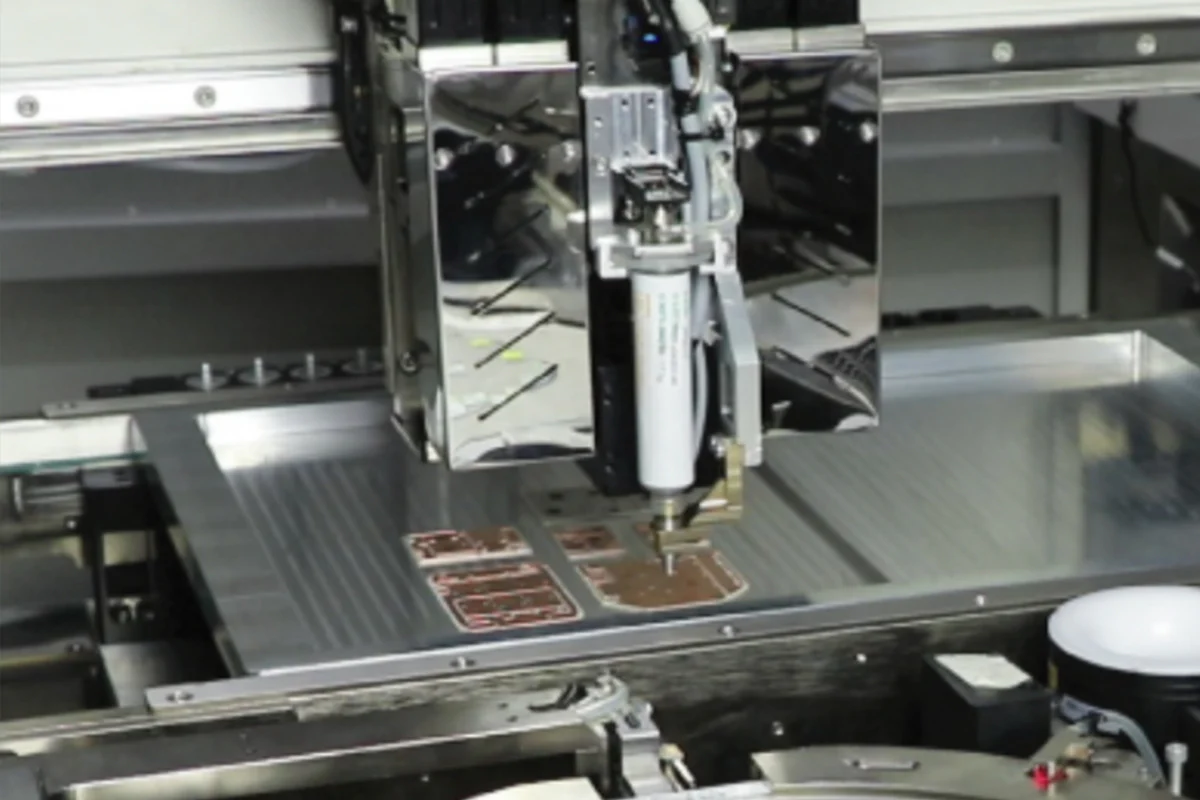

2. The Solder-plate feeder can feed and cut the required length of solder-plate, then placing to the DBC board by mounting head automatically;

3. The direct placement solder-plate can avoid various problems caused by flux and eliminate the occurrence of defective products;

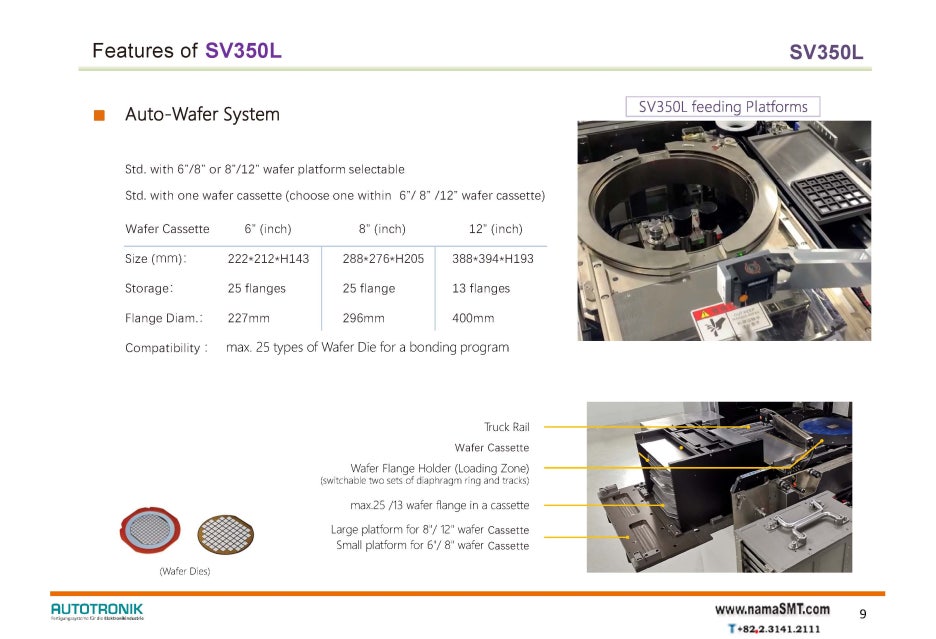

4. SV350L equipped with the Auto-wafer loading system, each wafer cassette can store up to 25 flanges and multi types of materials loading;

5. Can be placed with different specifications of material according to the processing program to max. 25 types of wafer flange materials in cassette;

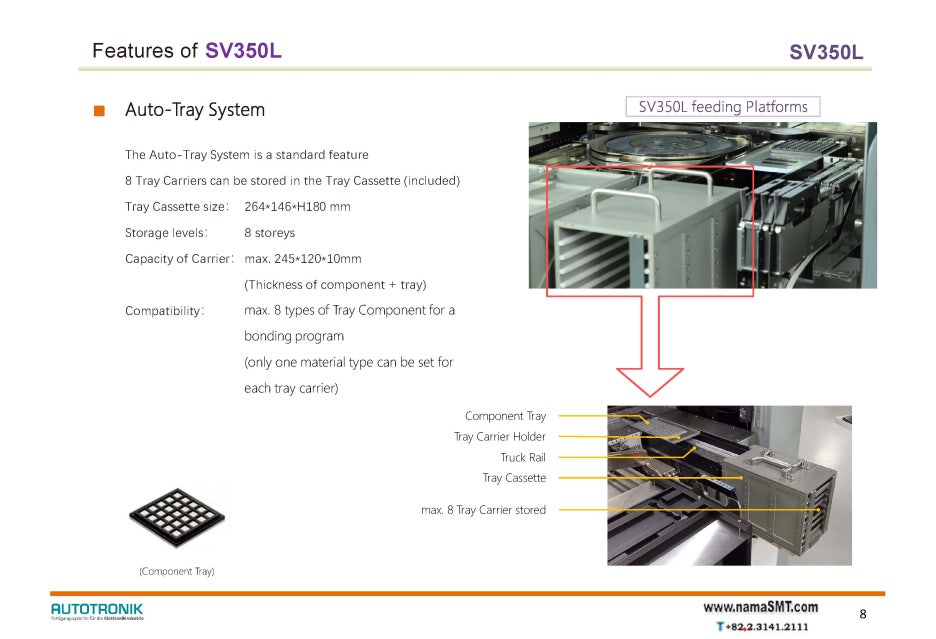

6. Adopted with Auto-tray feeding system, each Tray cassette can store 8 layers of tray carrier for component tray size max. 245*120mm of each;

7. Supported maximum 25 types of component material for auto-loading and placement in a processing program;

8. Auto-wafer and Auto-tray systems can quickly replace the material cassette to improve productivity.

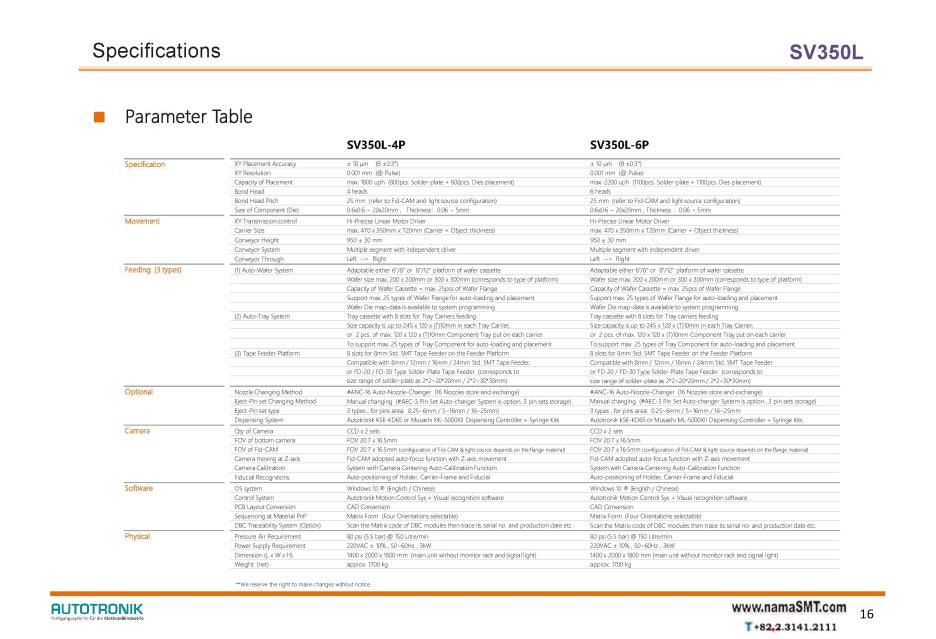

9. 4 heads and 6 heads of SV350L series selectable, convenient to handling different components types and productivity improved.

10. Formic acid vacuum reflow can improve DBC dies soldering ability, eliminate oxidation, and shorten process time.

Dis-advantage : Higher investment cost